-

How does it work?

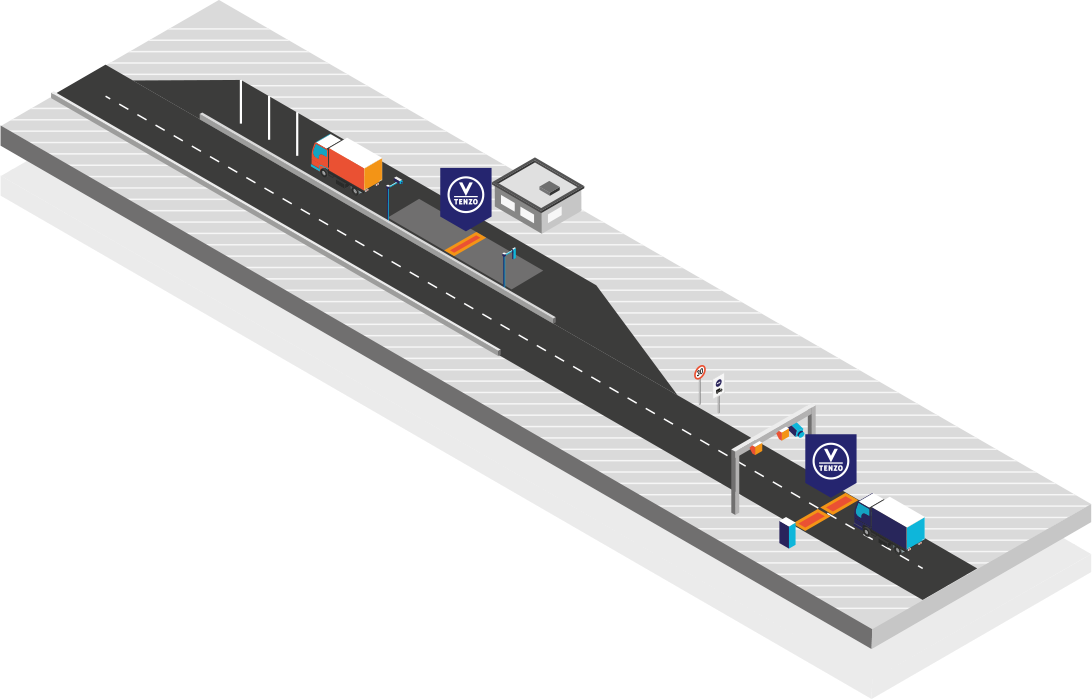

- Axle Weighing System TENZOWIM 134 evaluates loads of individual axles, axle groups and the gross vehicle weight (GVW) of the vehicle at the time when the vehicle passes over the weighing platform.

- Vehicles are weighted during passing the bridge, weighing is automatically evaluated and processed by computer. Their operation can be unattended.

- Weighing in motion brings significant efficiency gains and time-savings. Up to 300 trucks per hour can be weighed on sites with rush Traffic.

- TENZOWIM 134 has been certified for both commercial and for law-enforcement weighing in accordance with international recommendation OIML R134.

Vehicles are weighted automatically during passing the bridge

-

Main benefits

Automated & Unattended operation

The TENZOWIM 134 is an automated weighing instrument designed for work on unattended sites. High throughput.

Accurate weighing

TENZOWIM 134 provides a real-time, accurate information about the gross weight of the vehicle and its axles. Accuracy from 1%.

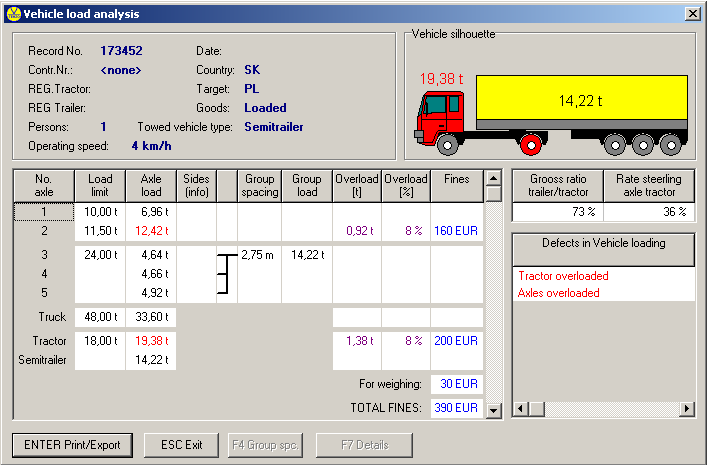

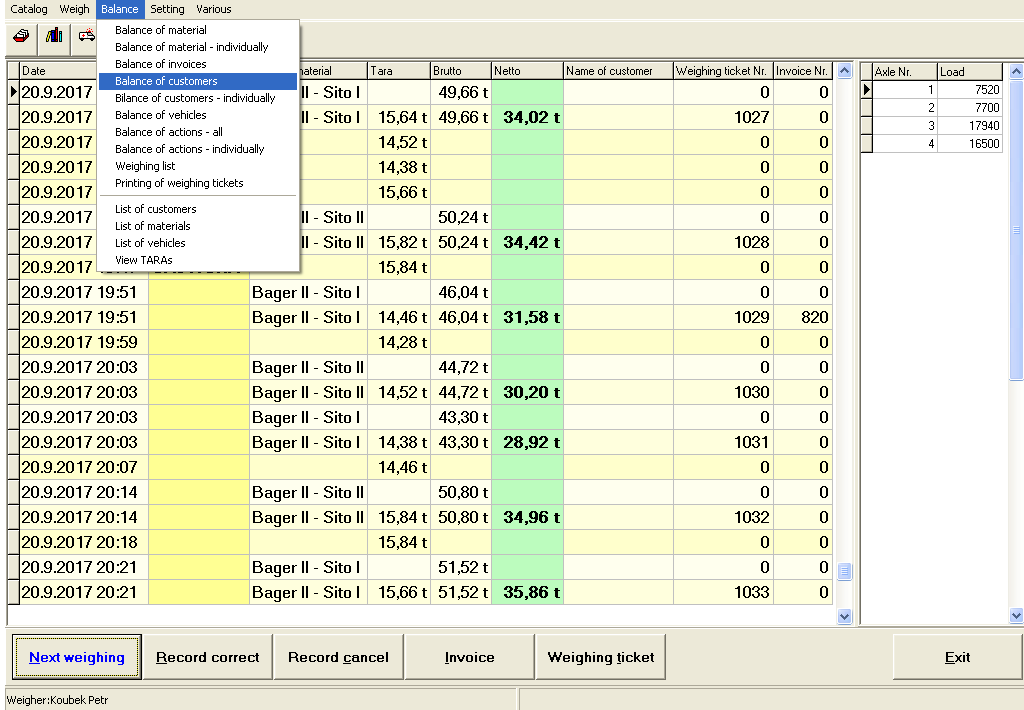

Smart software & On-line data

Automatic analysis of vehicle load according to national limits and for all subsequent steps of Law Enforcement process is ready to fulfil customer’s needs. Software generates weighing tickets or invoices.

Reliability in tough conditions

TENZOWIM 134 is ready to work in harsh weather conditions. Heating or air-conditioning accessories ensures reliable operation of scales even in the extreme temperatures. The weighing bridge has been protected against corrosion.

Diagnostics

Advanced diagnostics for preventive maintenance and maximum uptime. The 24/7 service supervision is available.Easy installation and maintenance

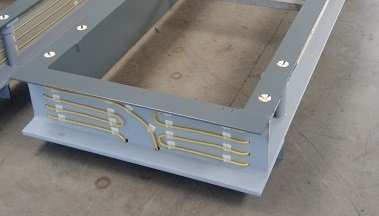

Weighing System TENZOWIM 134 is installed in a steel pit frame that is embedded into the weighing zone. The frame can be put into construction blocks without the concrete base. It can be concreted monolithically directly on site.

Weighing bridge can be easily picked up by a forklift at any time, and after cleaning or servicing the base it can be stored back without any recalibration by a service specialist. Regular maintenance of the scales is easier and reduces costs.Water and antifreeze protection

The concrete prefabricated base is equipped for drainage of rainwater. The standard heating element ensures reliable operation in the winter time while other weighing systems can suffer from freezing the base. The temperature in the base is automatically controlled. Heating is automatically switched on only at minus temperature to reduce electricity costs.

Automated operation

The TENZOWIM 134 is automatic weighing instrument. It weighs axles, detects axle groups, measure axle distances and vehicle speed by advanced evaluation algorithms without necessity of additional sensors or accessories. This reduce installation costs and cost of ownership.

-

Features

Parameter

Value

Verified capacity range (per axle) 200 to 20 000 kg Safe overloading per axle 30 000 kg No. of weighed axles unlimited Verified capacity range (total vehicle weight) unlimited Scale interval – approved “e” / adjustable “d” e= 20 kg / d = 10,20,50 kg Speed range at weighing (depending on the weighing system type) 1 – 50 km/h Accuracy class in static mode according to EN 45501 III Accuracy class of vehicle weight parameters in accordance with OIML R134 up to 1B (1% GVW, 2% axles) Measurement accuracy of total vehicle weight expressed in % better than 1% Measurement accuracy of axle weight expressed in % better than 2% Weighing system approved by the Czech Metrology Institute TCM 128/19 - 5651 Weighbridge

Platform operation profile 2 900 x 700 mm up to 4 000 x 900 mm Platform finishing Al–Zn coated (metalized) Load cells capacity 4 x 20 000 kg (~ 80 000 kg total) Load cells certification OIML R60, C3 class Load cells protection class IP68 / IP69K ANPR

Reliability of registration plate recognition at any light conditions > 95% Reliability of registration plate (license number) recognition at good light conditions > 98% -

Using The weighing at the first stage ensures fast pre-selection of overloaded vehicles from the traffic flow. Weighing system at the second or at third stage works with much higher accuracy that is suitable for direct charging for overloading.

Both stages can run continuously in fully automatic mode. Throughput of the final stage of weighing station is up to 300 vehicles per hour.

-

Extension

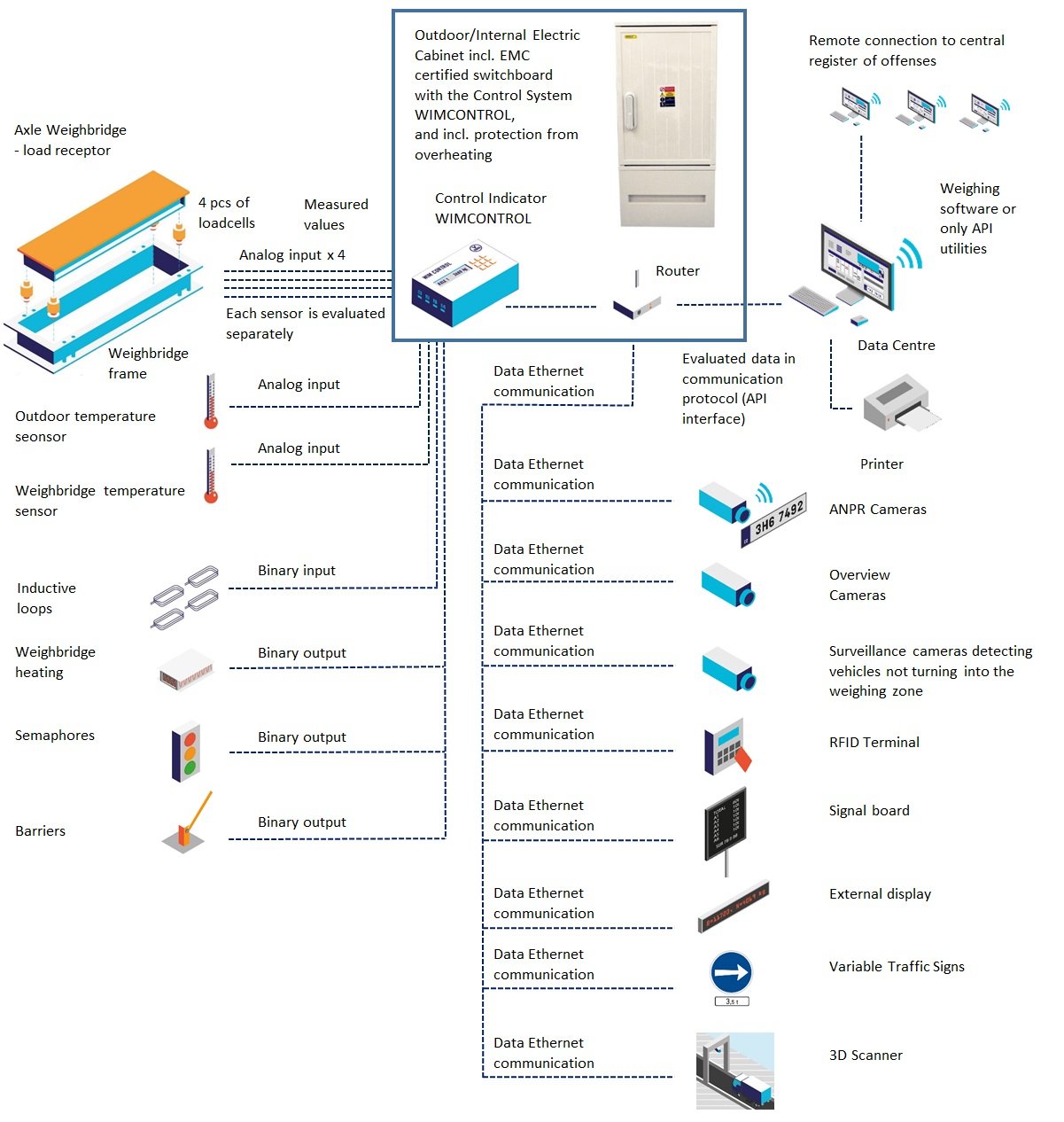

Extension the system with additional features and accessories

-

Building preparation The preparation of the weighing station is usually ensured by the client themselves or by a designated organization based on a standard project supplied. Contact TENZOVAHY for more details!

Axle Weighbridge TENZOWIM 134 for vehicles

Axle Weighing System TENZOWIM 134 has been designed for fast and accurate weighing of vehicles in motion (WIM). TENZOWIM 134 is advanced weighing equipment suited for law enforcement weighing as well as for weighing in logistics terminals, in forwarding, in quarries and construction companies. The system TENZOWIM 134 is characterized by low operating costs and by high operational accuracy.